CUPOLEX® Plastic Dome Concrete Forms are stay-in-place forms to create unreinforced or reinforced concrete slabs on grade and other concrete structures. Concrete is poured over the modular dome forms to create floating or structural slabs on grade. The unique concrete geometry Cupolex creates, forms an under slab void that can be vented to remove moisture and soil gases or provide solutions for various sustainable construction applications – uses less concrete and reinforcing than a standard slab with equivalent load bearing capacity.

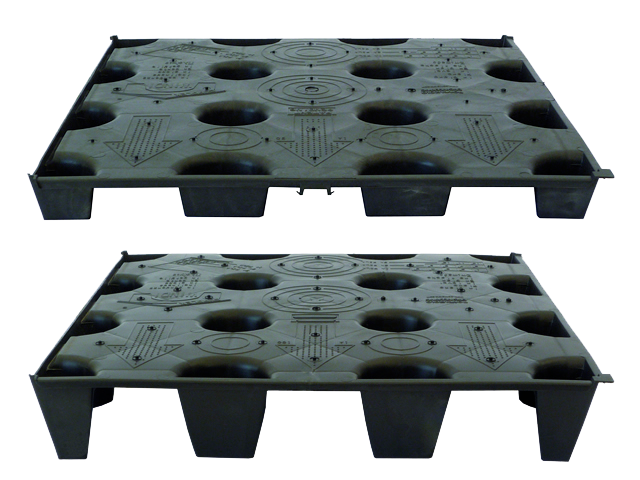

CUPOLEX® Patented Forms have unique connecting features. Only, CUPOLEX® forms additional built-in plastic at all pressure point locations and a central reinforced cone support of equal height to the element and positioned in correspondence of the central region, guarantees the absorption of vibrations which occurs during the finishing of the concrete Aerated floor slab.

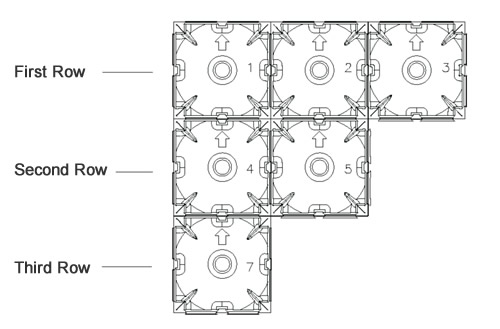

Cupolex® provides Excellent Flexibility in Working with new construction or remodeled building layouts. The main characteristics of the forming system are speed and simplicity, with maximum benefits being realized when the Cupolex system is engineered during the early design stages in assessing site and soil conditions, considering elevations of various sections of the slab area that may have to be raised of for example if strip footings, walls or other typically formed sections can be incorporated within the system, cost savings and environmental benefits can be realized.

On average two laborers set 140 m2/hr (1500 sf/hr)

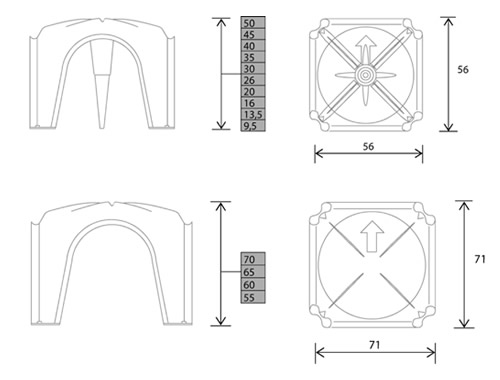

Cupolex® forms are available and various heights to suit any site conditions or design requirements. Made from 100% recycled Polypropylene (PP) plastic. The forms provide the maximum performance and guarantees superior characteristics of stability and resistance in its structure to allow operations that are completed directly above the plastic Cupolex® elements before and during the placement of the concrete.

| Form Type | Overall Form Depth |

Plan Dimension Installed |

Concrete Consumption To Top of Domes |

Clear Void Equivalent |

Dead Load of Concrete Structure to Top of Domes |

|---|---|---|---|---|---|

| cm (inch) | cm (inch) | m3/m2 (cy./sq.ft.) | cm (inch) | kPa (psf) | |

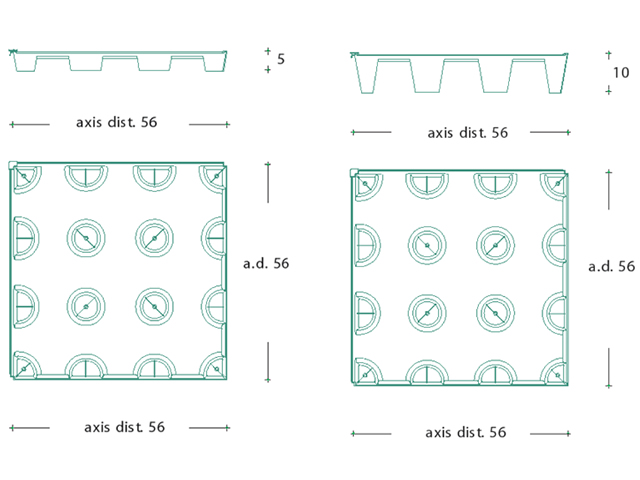

| WINDI 5-56 | 5 (2") | 56x56 (22"x22") | 0.008(0.0010) | 4 (1.57") | 0.19 (3.96) |

| WINDI 10-56 | 10 (4") | 56x56 (22"x22") | 0.030(0.0036) | 7 (2.76") | 0.71 (14.82) |

| CUPOLEX 9.5-56 | 9,5 (4") | 56x56 (22"x22") | 0.014 (0.0017) | 8 (3.15") | 0.33 (6.89) |

| CUPOLEX 13.5-56 | 13,5 (5") | 56x56 (22"x22") | 0.030 (0.0036) | 11 (4.33") | 0.71 (14.82) |

| CUPOLEX 16-56 | 16 (6") | 56x56 (22"x22") | 0.035 (0.0043) | 14 (5.50") | 0.83 (17.33) |

| CUPOLEX 20-56 | 20 (8") | 56x56 (22"x22") | 0.035 (0.0043) | 17 (6.69") | 0.83 (17.33) |

| CUPOLEX 26-56 | 26 (10") | 56x56 (22"x22") | 0.035 (0.0055) | 22 (58.66") | 0.83 (17.33) |

| CUPOLEX 30-56 | 30 (12") | 56x56 (22"x22") | 0.042 (0.0051) | 26 (10.24") | 0.99 (20.67) |

| CUPOLEX 35- 56 | 35 (14") | 56x56 (22"x22") | 0.045 (0.0055) | 31 (12.20") | 1.06 (22.13) |

| CUPOLEX 40-56 | 40 (16") | 56x56 (22"x22") | 0.060 (0.0073) | 34 (13.39") | 1.42 (29.65) |

| CUPOLEX 45-56 | 45 (18") | 56x56 (22"x22") | 0.064 (0.0078) | 39 (15.35") | 1.51 (31.53) |

| CUPOLEX 50-56 | 50 (20") | 56x56 (22"x22") | 0.065 (0.0079) | 44 (17.32") | 1.53 (31.95) |

| CUPOLEX 55-71 | 55 (22") | 71x71 (28"x28") | 0.069 (0.0080) | 48 (19.29") | 1.63 (34.04) |

| CUPOLEX 60-71 | 60 (24") | 71x71 (28"x28") | 0.070 (0.0085) | 53 (20.87") | 1.65 (34.46) |

| CUPOLEX 65-71 | 65 (26") | 71x71 (28"x28") | 0.071 (0.0090) | 58 (22.83") | 1.68 (35.08) |

| CUPOLEX 70-71 | 70 (28") | 71x71 (28"x28") | 0.073 (0.0095) | 63 (24.80") | 1.72 (35.92) |

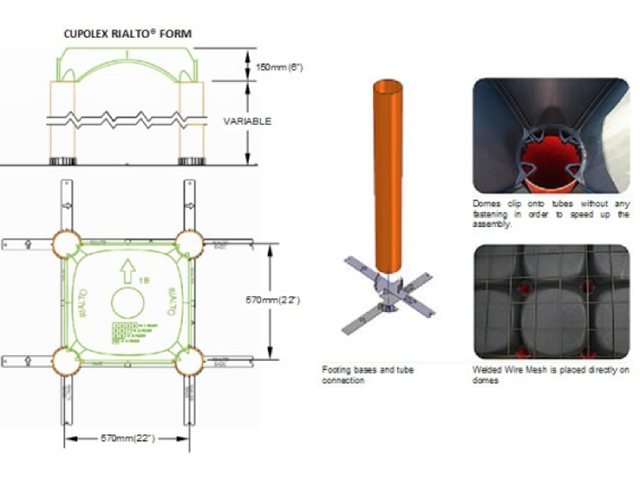

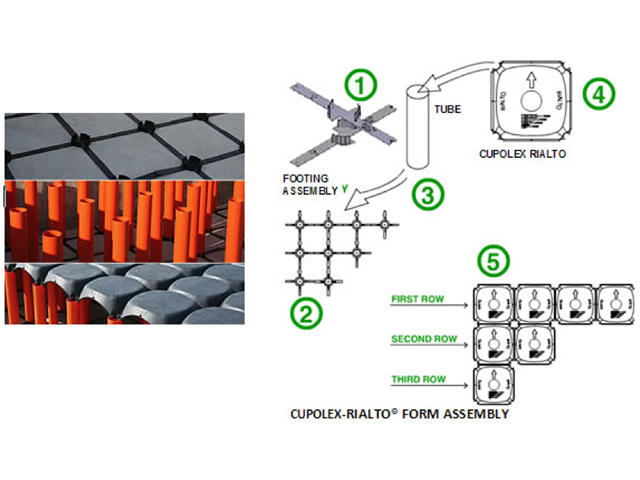

CUPOLEX®-RIALTO® is a forming system for providing an easy, efficient and fast solution for constructing an aerated floor with heights from 500mm (20 inches) to 2500mm (100 inches). This cutting edge forming system comprises of CUPOLEX domes, pipes and bases that quickly interlock and connect to each other composing a self bearing structure ready for the placement of a concrete slab. The elevated CUPOLEX® slab supported by the matrix of columns formed by the pipes allows the system for high load-bearing capacities and the elevated CUPOLEX® RIALTO® structure and the void created below the slab can be used for various purposes and applications.All components that make up the CUPOLEX®-RIALTO® forming system are made from 100% recycled plastic.

CUPOLEX® RIALTO® slab on grade systems provide the most cost effective and sustainable solutions to conventional thickened slab designs. CUPOLEX® RIALTO® crawl space foundations provide solutions to moisture, mold, and venting problems that have been common to old fashioned crawl space foundation designs. CUPOLEX® RIALTO® slabs replace gravel or any other fill typically required below slabs constructed on native or engineered sub-grades consisting of low to non-expansive characteristics. RIALTO® slabs also replace expensive rigid insulation typically used for creating floating concrete slabs on existing structures when weight limit is a factor.

| Overall Form Depth | Plan Dimension Installed | Concrete Consumption to top of Domes | Clear Void Equivalent | Dead Load of Concrete Structure to Top of Domes |

|---|---|---|---|---|

| cm (inch) | cm (inch) | m3/m2 (cy./sq.ft.) | cm (inch) | kPa (psf) |

| 25 (10") | 57x57(23"x23") | 0.025(0.0055) | 10 (4.0") | 0.60 (12.5) |

| 30 (12") | 57x57(23"x23") | 0.027 (0.0030) | 15 (6.0) | 0.65 (13.5) |

| 35 (14") | 57x57(23"x23") | 0.030 (0.0033) | 20 (8.0") | 0.70 (14.6) |

| 40 (16") | 57x57(23"x23") | 0.032(0.0036) | 25 (10.0") | 0.75 (15.6) |

| 45 (18") | 57x57(23"x23") | 0.034 (0.0039) | 30 (12.0") | 0.80 (16.7) |

| 50 (20") | 57x57(23"x23") | 0.036 (0.0043) | 35 (14.0) | 0.85 (17.7) |

| 55 (22") | 57x57(23"x23") | 0.038 (0.0045) | 40 (16.0") | 0.90 (18.8) |

| 60 (24") | 57x57(23"x23") | 0.040 (0.0048) | 45 (18.0") | 0.95 (19.8) |

| 65 (26") | 57x57(23"x23") | 0.042 (0.0051) | 50 (20.0") | 1.00 (20.9) |

| 70 (28") | 57x57(23"x23") | 0.044 (0.0054) | 55 (22.0") | 1.05 (21.9) |

| 80 (30") | 57x57(23"x23") | 0.046 (0.0057) | 60 (24.0") | 1.10 (23.0) |

| 85 (32") | 57x57(23"x23") | 0.048 (0.0060) | 65 (26.0") | 1.15 (24.0) |

| 90 (34") | 57x57(23"x23") | 0.050 (0.0063) | 70 (28.0") | 1.20 (25.1) |

| 95(36") | 57x57(23"x23") | 0.052 (0.0066) | 75 (30.0") | 1.25 (26.1) |

| 100 (38") | 57x57(23"x23") | 0.054 (0.0069) | 80 (32.0") | 1.30 (27.2) |

| 105 (40") | 57x57(23"x23") | 0.056 (0.0072) | 85 (34.0") | 1.35 (28.2) |

| 110 (42") | 57x57(23"x23") | 0.058 (0.0075) | 90 (36.0") | 1.40 (29.3) |

| 115 (44") | 57x57(23"x23") | 0.060 (0.0078) | 95 (38.0") | 1.45 (30.3) |

| 120 (46") | 57x57(23"x23") | 0.062 (0.0081) | 100 (40.0") | 1.50 (31.4) |

| 125 (48") | 57x57(23"x23") | 0.064 (0.0084) | 105 (42.0") | 1.55 (32.4) |

| 130 (50") | 57x57(23"x23") | 0.066 (0.0087) | 110 (44.0") | 1.60 (33.5) |

| 135 (52") | 57x57(23"x23") | 0.068 (0.0090) | 115 (46.0") | 1.65 (34.5) |

| 140 (54") | 57x57(23"x23") | 0.070 (0.0093) | 120 (48.0") | 1.70 (35.6) |

| 145 (56") | 57x57(23"x23") | 0.072 (0.0096) | 125 (50.0") | 1.75 (36.6) |

| 150 (58") | 57x57(23"x23") | 0.074 (0.010) | 130 (52.0") | 1.80 (37.7) |

| 155 (60") | 57x57(23"x23") | 0.076 (0.0103) | 135 (54.0") | 1.85 (38.7) |

| 160 (62") | 57x57(23"x23") | 0.078 (0.0106) | 140 (56.0") | 1.90 (39.8) |

| 165 (64") | 57x57(23"x23") | 0.080 (0.0109) | 145 (58.0") | 1.95 (40.9) |

| 170 (66") | 57x57(23"x23") | 0.082 (0.0112) | 150 (60.0") | 2.00 (41.8) |

| 175(68") | 57x57(23"x23") | 0.084 (0.0115) | 155 (62.0") | 2.05 (42.8) |

| 180 (70") | 57x57(23"x23") | 0.086 (0.0118) | 160 (64.0") | 2.10 (43.9) |

| 185 (72") | 57x57(23"x23") | 0.088 (0.0121) | 165 (66.0") | 2.15 (44.9) |

| 190 (74") | 57x57(23"x23") | 0.090 (0.0124) | 170 (68.0") | 2.20 (46.0) |

| 195 (76") | 57x57(23"x23") | 0.092 (0.0127) | 175 (70.0") | 2.25 (47.0) |

| 200 (78") | 57x57(23"x23") | 0.094 (0.0130) | 180 (72.0") | 2.30 (48.0) |

| 205 (80") | 57x57(23"x23") | 0.096 (0.0134) | 185 (74.0") | 2.35 (49.0) |

CUPOLEX®-WINDI® creates a ventilated floor in new or remodeled building without affecting the structure of the building. The adoption of CUPOLEX®-WINDI® allows you to save on waterproof sheathing and guarantees a constant seal against dampness. CUPOLEX®-WINDI® may also be easily attached to walls to obtain an air space capable of ventilating and eliminating mold and installed to create ventilated flat or pitched roofs.

| Form Type | Overall Form Depth | Plan Dimension Installed | Concrete Consumption To Top of Domes | Clear Void Equivalent | Dead Load of Concrete Structure to Top of Domes |

|---|---|---|---|---|---|

| cm (inch) | cm (inch) | m3/m2 (cy./sq.ft.) | cm (inch) | kPa (psf) | |

| CUPOLEX WINDI 5-56 | 5 (2") | 56x56 (22"x22") | 0.008(0.0010) | 4 (1.57") | 0.19 (3.96) |

| CUPOLEX WINDI 10-56 | 10 (4) | 56x56 (22"x22") | 0.030(0.0036) | 7 (2.76") | 0.71 (14.82) |

7 Oak Place • Montclair, New Jersey 07042

(973) 687-4399